News

How Composite Cans, Paperboard Cores, and Tubes Are Used in the Paper Manufacturers & Converters Industry

The paper manufacturers and converters industry relies on efficient, durable, and sustainable packaging solutions to handle and transport rolled materials, such as paper, films, and labels. Paper Tubes and Sales Manufacturing (PTS), based in Dallas, Texas, has been a leader in this space for over 35 years, producing high-quality composite cans, paperboard cores, and tubes made from 100% recycled materials. Operating from a 60,000-square-foot facility with nationwide distribution, PTS delivers customized, eco-friendly solutions that meet the specific needs of paper manufacturers and converters, ensuring product protection, operational efficiency, and environmental responsibility.

Composite Cans for Secure Storage and Shipping

Composite cans from PTS, featuring poly-foil linings and heat-sealed metal tops, are ideal for storing and shipping sensitive paper products like specialty papers or coated films. These cans, available with custom-fitted closures or tamper-evident tops, protect against moisture, oxygen, and physical damage, ensuring the integrity of high-value materials during transport or long-term storage. For paper converters, PTS’s ability to print vibrant, custom labels enhances brand visibility, while the cans’ skived body design improves column strength, making them suitable for stacking and handling in high-volume converting operations.Paperboard Cores for Precision Winding

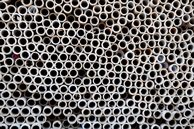

Paperboard cores are critical for paper manufacturers and converters handling rolled products like newsprint, tissue, or adhesive labels. PTS produces cores up to 30 inches in diameter with precise tolerances and customizable wall thicknesses, ensuring compatibility with high-speed winding and unwinding equipment. These cores, made from 100% recycled paperboard, provide the strength needed to support heavy rolls without deformation, reducing downtime in converting processes. PTS’s in-house engineering team tailors core specifications to meet exact requirements, such as wax coatings for outdoor storage or metal plugs for added durability.Paperboard Tubes for Versatile Applications

PTS’s paperboard tubes, including mailing and shipping tubes, serve paper manufacturers and converters by securely transporting rolled documents, blueprints, or posters. Available with plastic or metal end caps (75% recycled metal), these tubes prevent bending and damage during shipping. Custom printing options allow converters to add logos or designs, enhancing professionalism for clients in publishing or advertising. The tubes’ eco-friendly construction aligns with the industry’s sustainability goals, reducing environmental impact while meeting the demand for reliable, cost-effective packaging solutions.Benefits of PTS’s Solutions

PTS’s commitment to sustainability, using 100% recycled paperboard and refurbished pallets, resonates with paper manufacturers and converters aiming to reduce waste. Their state-of-the-art equipment, five winding lines, and in-house machine shop enable rapid turnaround—stock products ship in 2–3 days, custom orders within two weeks. Nationwide distribution via their own fleet ensures timely delivery, while competitive pricing and personalized service make PTS a trusted partner. For paper manufacturers and converters seeking durable, green packaging, contact PTS. Call at 800-422-5108 or use our contact form.If you’re looking for “GREEN,” look no further than PTS! After all, green is the color of PTS.