News

November 2025 - Picking a Shipping Tube for Posters, Blueprints, and Documents

Learn how to choose the right shipping tube for posters, blueprints, and documents. Compare materials, wall thickness, closures, and branding options to protect items and reduce costs...

Continue Reading.August 2025 - How Composite Cans, Paperboard Cores, and Tubes Are Used in Toy Manufacturing

Paper Tubes and Sales Manufacturing empowers toy manufacturers by delivering composite cans, paperboard cores, and tubes that enhance packaging, production, and design while prioritizing safety and sustainability...

Continue Reading.April 2025 - How to Select a Manufacturer of Paper Tubes, Cores, and Composite Cans

Choosing the right manufacturer for paper tubes, cores, and composite cans is critical for businesses in industries ranging from food packaging to industrial manufacturing. These packaging solutions...

Continue Reading.October 2016 - Why Sustainability Is Important to Us

Did you know that in the U.S. alone, the waste management industry brings in revenues of $75 billion per year (gridwaste.com). That number wouldn’t be so high if it weren’t for the huge volume of waste that companies across the country are generating every single day.

Continue Reading.September 2016 - New Product News: Doner Kebab Tubes

Have you tasted a delicious doner kebab from a local deli, or do you enjoy sinking your teeth into a tasty shawarma? If your mouth is watering at the mention of these savory dishes, the answer is probably yes. Part of what makes the meat so delicious in these popular menu items is the method

Continue Reading.September 2016 - Cardboard Mailing & Shipping Tubes from PTS

We live in a busy world where legal files, documents and other special items are continually being sent from one place to the next. Most businesses rely on the mail or a private courier so help them send and receive things that are critical to their operation. Even though email makes it...

Continue Reading.September 2016 - Tape and Label Cores from PTS Manufacturing

Have you ever wondered where the cores of your rolls of packing tape or labels come from? After all, they have to be made somewhere. Well, they’re made by manufacturers like PTS. We make these cores from paper products and then...

Continue Reading.October 2016 Understanding Success and Soap Stick Tubes.

The thing we do best outside of providing high quality paper tubes and core products, is understanding our strengths and catering our business around those strengths....

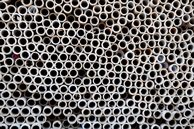

Continue Reading.High Quality Paper Cores and Rigid Packaging

Paper Tubes & Sales manufacturing is proud to be leaders in providing high quality paper rigid packaging and paper cores among a wide variety of other services. We have ....

Continue Reading.March 2016 - Industrial Packaging Division

For over 27 years, Paper Tubes & Sales has been at the forefront of the paper tube and packaging industry through utilizing our experiences and knowledge to provide top of the line products to our customers. We are proud to say that we are one of the largest independent manufacturers of paper cores, tubes and composite cans in the United States of America...

Continue Reading.July 2008 - Can division plant upgrade completed.

Dallas, TX, July 2008 - Paper Tubes and Sales announces the completion of the upgrade to their Can Division Plant....

Continue Reading.July 2008 - Can division plant upgrade completed.

Dallas, TX, July 2008 - Paper Tubes and Sales announces the completion of the upgrade to their Can Division Plant....

Continue Reading.If you’re looking for “GREEN,” look no further than PTS! After all, green is the color of PTS.